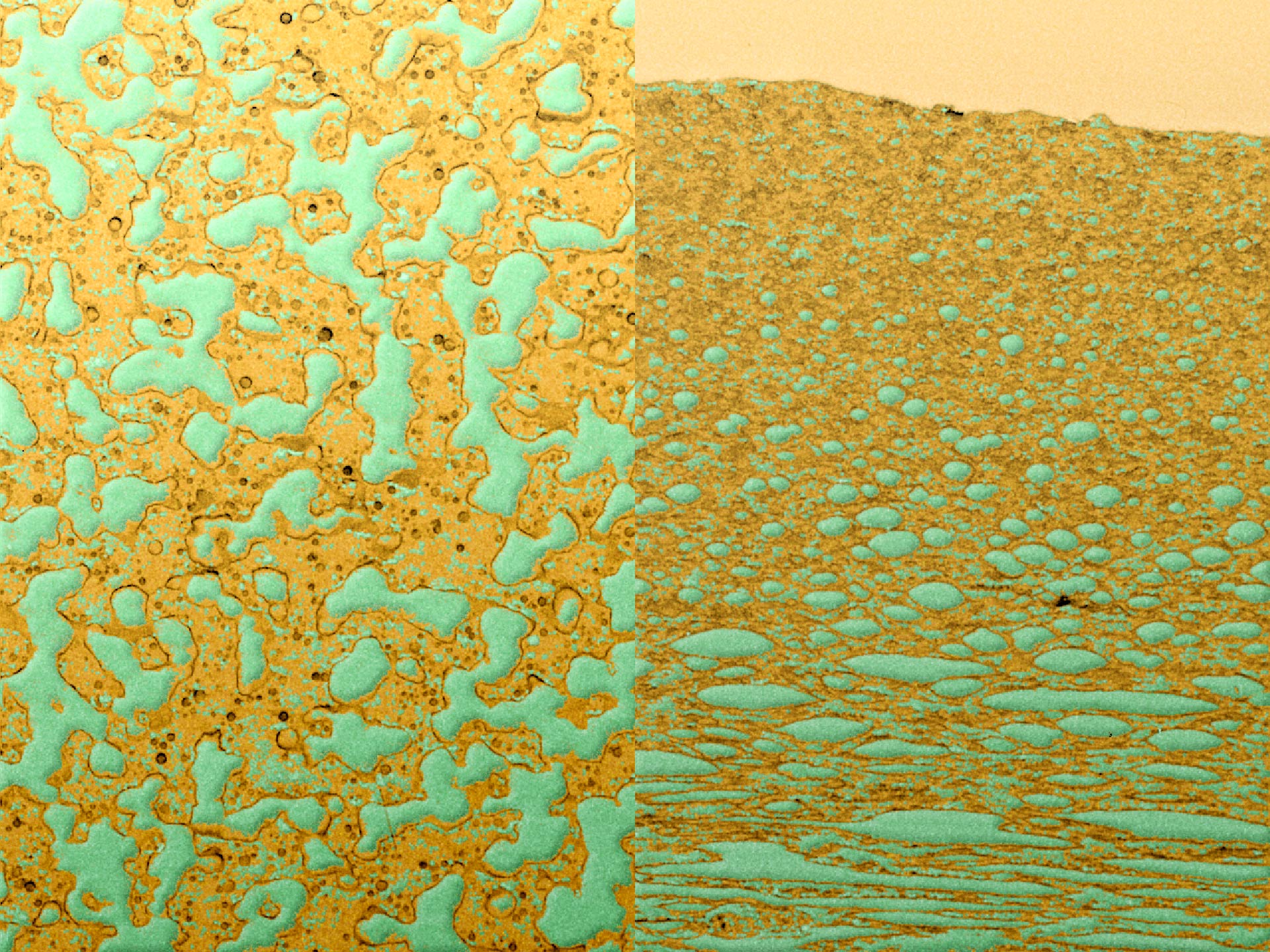

Developed in 1974 using Sekisui Kasei's proprietary polymer hybrid technology, PIOCELAN is a unique foamed resin that has a highly optimized combination of polystyrene and polyolefin properties: "rigidity, expandability, heat insulation" and "impact resistance, chemical resistance, wear resistance".

Conventionally, polystyrene has excellent rigidity, expandability, and heat insulation properties, but it has weaknesses in "impact resistance, chemical resistance, and wear resistance". Sekisui Kasei has compounded polyolefin with this polystyrene. By combining the properties of both materials, new applications have become possible.

Since its development half a century ago, the opportunities to use the ever-evolving PIOCELAN have been expanding due to its high convenience and excellent environmental adaptability.

PIOCELAN can exhibit higher impact resistance than conventional expanded polystyrene (EPS) and expanded polypropylene (EPP). By selecting the grade at the time of design and customizing the material, it is possible to create a design that freely balances performance, weight, and cost.

These performances are suitable for applications such as "protecting the inside from external shocks"; therefore, PIOCELAN can be used as a shock absorption material for various parts of an automobile to reduce the impact on occupants and pedestrians in the event of an accident, thereby increasing safety. It is also used as a cushioning material for precision machinery and high-tech products to protect them from external shocks and vibrations during transportation.

Compared to conventional polypropylene and polystyrene, PIOCELAN has superior overall mechanical properties and exhibits high dimensional stability during molding. These properties enable precise and complex designs and styling in fields where the use of foamed resins was not previously envisioned.

Since automobiles move and are subjected to vibrations both internally and externally, any gaps between parts or inadequate dimensions can cause chattering and creaking noises. These problems can be solved by the high dimensional stability and rigidity of PIOCELAN.

PIOCELAN is a unique foamed resin that is a composite of polystyrene and polyolefin. By adjusting various physical properties using Sekisui Kasei's proprietary polymer hybrid technology, it is possible to customize PIOCELAN beyond its basic properties to provide extremely high impact absorbability or flexibility suitable for extremely complex shape designs.

In addition, a variety of grades are available to meet application requirements, including grades with antistatic properties for packing electronic components.

Furthermore, our technical team with years of design know-how and a thorough knowledge of PIOCELAN will select the most suitable grade and propose customization to meet your needs.

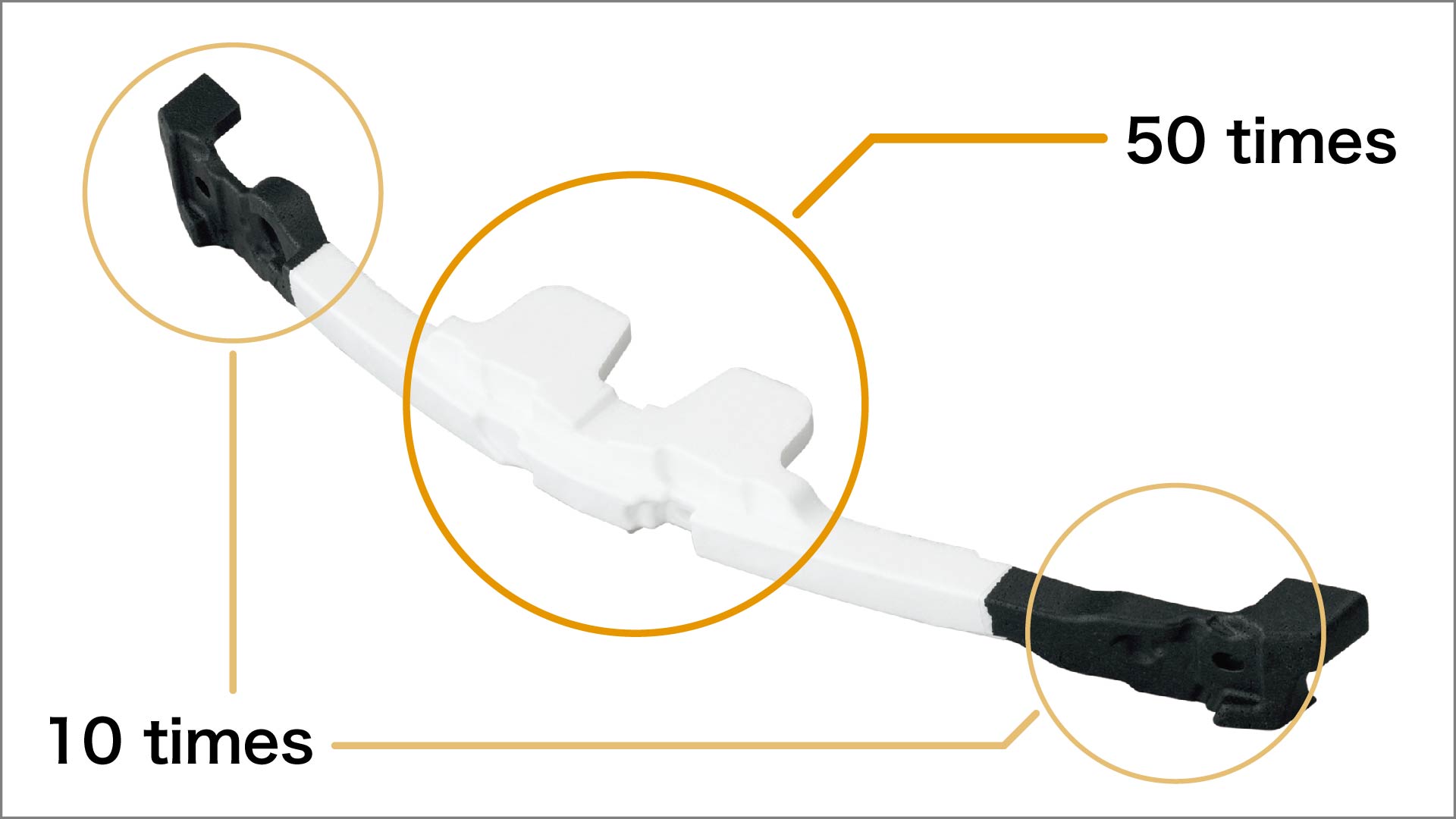

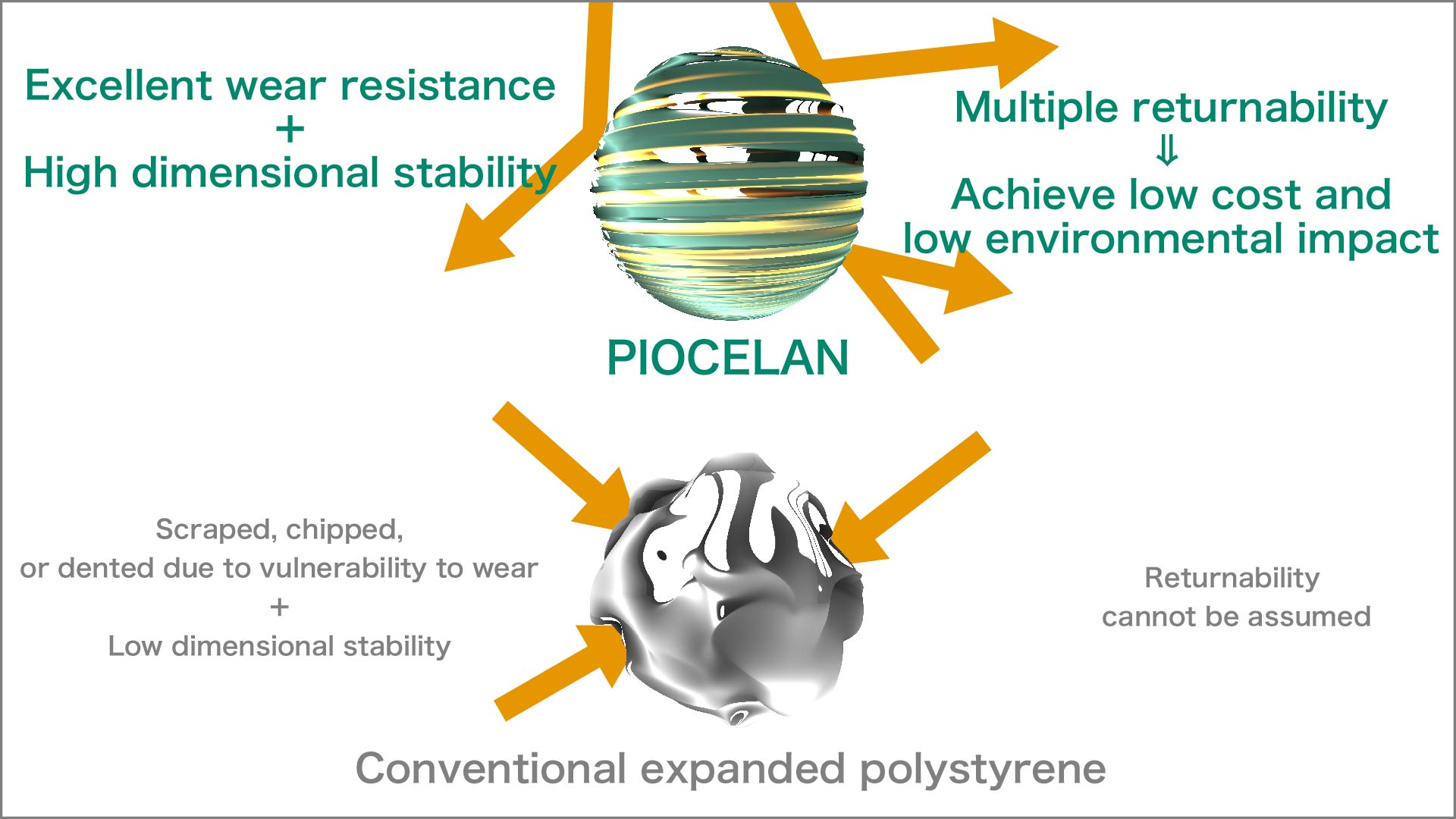

Conventional expanded polystyrene is subject to scraping, chipping and denting due to wear, but PIOCELAN, with its superior wear resistance, overcomes this weakness.

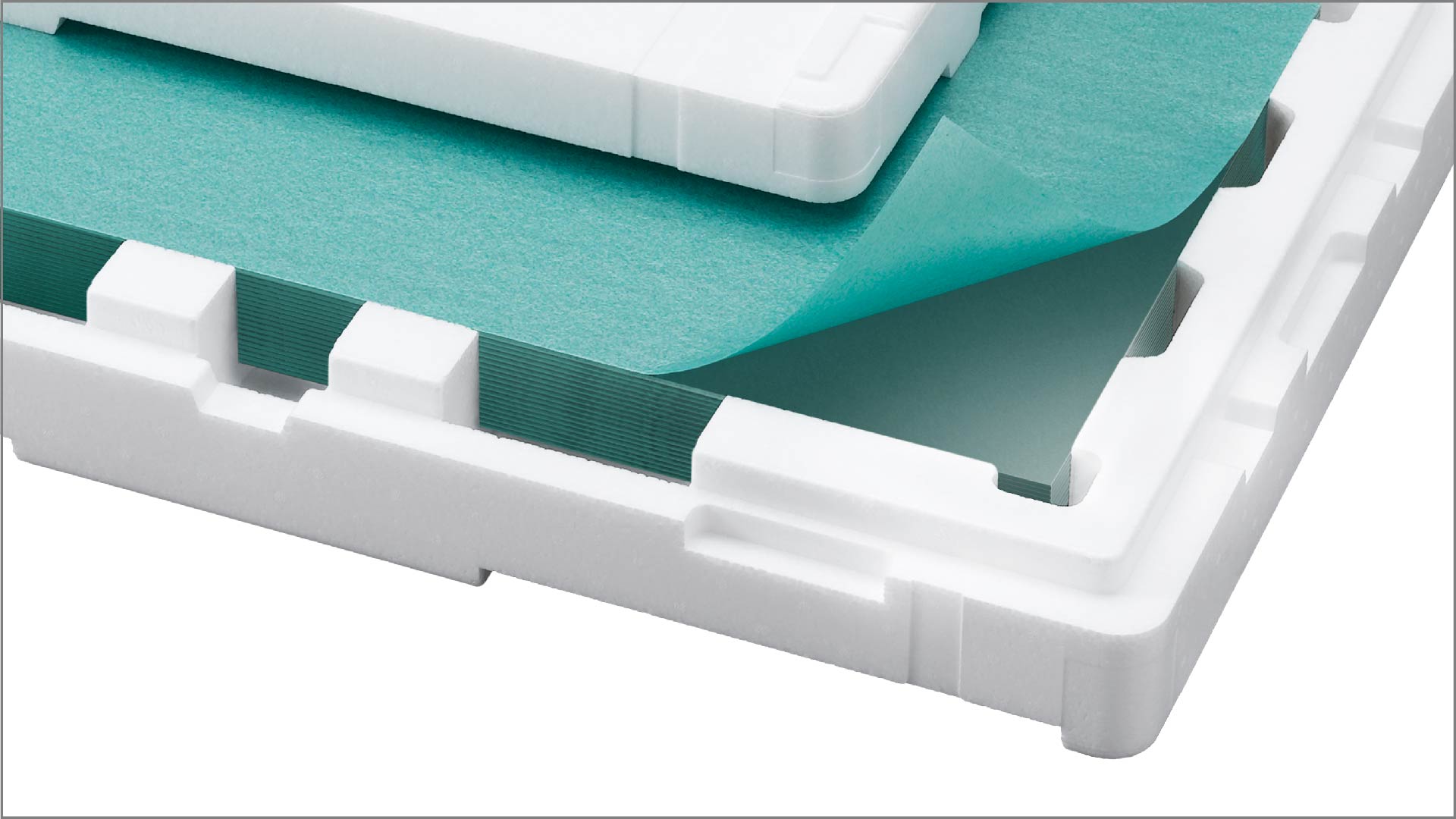

In addition, PIOCELAN is "returnable" (reusable) due to its high dimensional stability and excellent impact resistance.

When used for applications such as packing materials for use in transportation, it is possible to reduce costs and environmental impact with this excellent anti-wear performance through multiple returnability, which was difficult with conventional foamed resin packing materials.

The Sekisui Kasei Group has certified "packing materials for transporting automobile parts" and "flat-panel TV glass / panel transport containers", which are molded products using PIOCELAN, as "sustainable star products" * (environmentally friendly products).

Certification criteria established as part of the action plan "SKG-5R" to realize the "contribution to a sustainable society" set forth by the Sekisui Kasei Group (SKG). We internally certify products that reduce environmental impact and take into consideration limited resources as "Sustainable Products", and products that have a particularly high degree of contribution to the environment as "sustainable star products" (environmentally friendly products), thereby promoting their creation and market expansion.

PIOCELAN is more resistant to chemicals and oil than conventional expanded polystyrene, and is unaffected by adjacent members even if it is used for automobile parts or container transport containers where various chemicals and oils are nearby. As a result, PIOCELAN can stably demonstrate its original performance without being affected by adjacent parts.

The increase in cost, size, and weight that would have resulted from problems such as the need for a multi-layered structure to achieve a tight seal, and the need for a large spatial margin to reduce the impact of the system can be avoided.

| PIOCELAN | Expanded polystyrene | |

|---|---|---|

| Methyl ethyl ketone | × | × |

| Methyl alcohol | ○ | ○ |

| Hydrochloric acid (35%) | ○ | △ |

| Sodium hydroxide (10%) | ○ | ○ |

| Citric acid | ○ | ○ |

| Ethyl acetate | ○ | × |

| Carbon tetrachloride | ○ | × |

| Gasoline | ○ | △ |

| Kerosene | ○ | △ |

| Machine oil | ○ | ○ ~ △ |

| Cooking oil | ○ | ○ ~ △ |

| Plasticizer (DOP) | ○ | △ |

| Plasticizer (DBP) | △ | × |

○:No change △:Surface shrinkage ×:Surface depression

| ||

[Measurement method] Coated the surface of the test piece with 1.5 ml of the chemical and visually judged the surface condition

Measurement temperature: 20℃, Coating period: 7 days, Sample: OP-15D (15x)

Please feel free to contact us

should you have any comments or questions.