PIOCELAN is a unique foamed resin that has a highly optimized combination of polystyrene and polyolefin properties. Since its development half a century ago, PIOCELAN has been expanding into fields that were previously unimaginable due to its unique features, combined with the needs of our customers and technical capabilities of Sekisui Kasei.

Here is an introduction to the fields in which PIOCELAN is particularly active.

Low fuel consumption, light weight, safety performance, and low environmental impact ...... Modern cars, which are constantly required to have the highest standards of performance, are at the forefront of technological innovation.

In the automobile industry, PIOCELAN has been adopted by all eight major Japanese automobile manufacturers as an internal constituent member of vehicles.

Since 2001, there has been a rapid expansion in the adoption of PIOCELAN by Japanese automobile manufacturers.

Since 2006, PIOCELAN has been adopted by all eight major Japanese automobile manufacturers.

Since 2010, manufacturers all over the world have been adopting or considering adopting PIOCELAN.

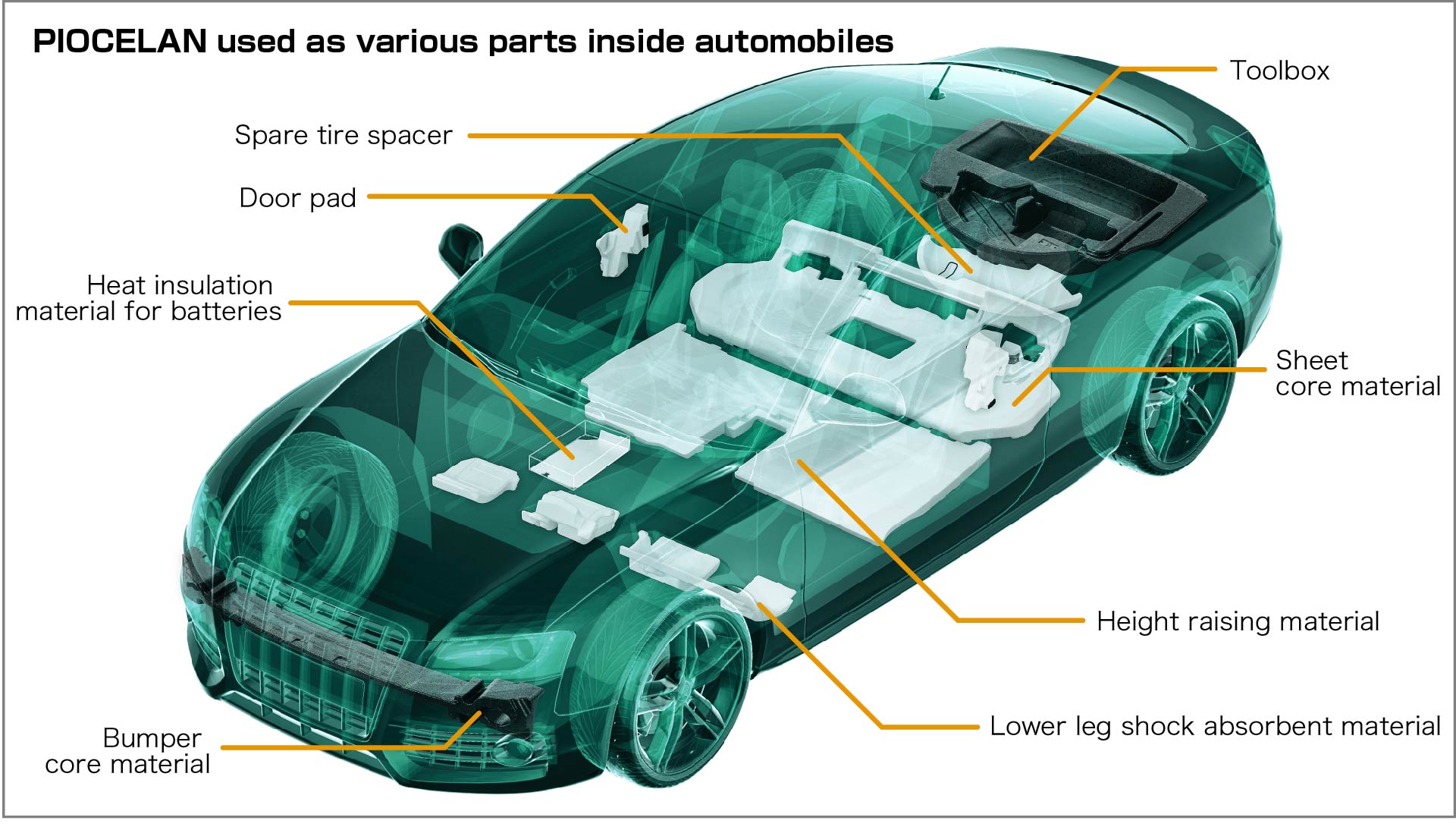

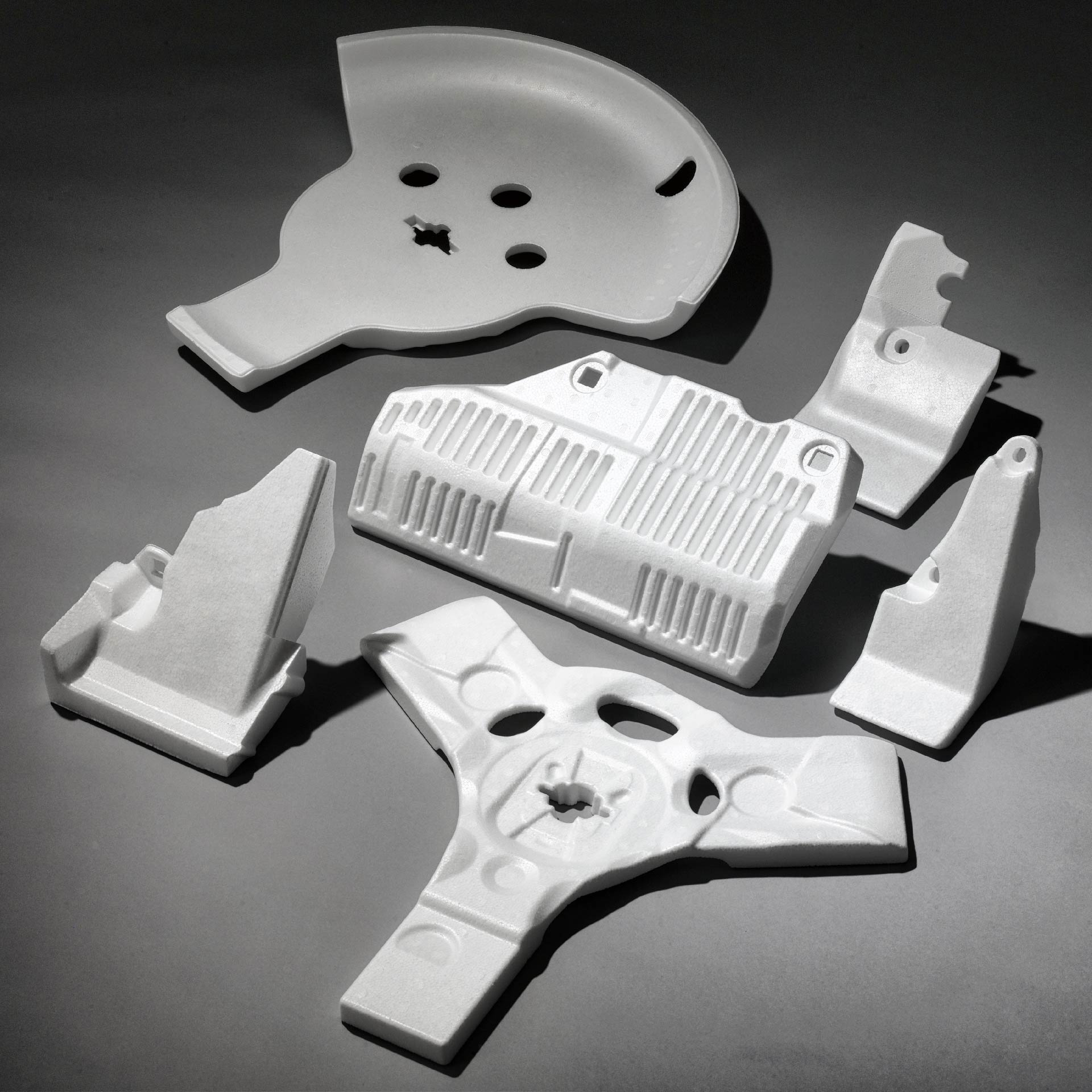

PIOCELAN is now used in various applications, including collision safety applications such as bumper core material and lower leg shock absorbent material, vibration absorption applications such as spare tire spacers and floor spacers, and interior molding applications such as steering column covers and cup holder core material. Here is an introduction to what properties of PIOCELAN are being utilized.

PIOCELAN, which exhibits 1.2 times higher impact resistance when compared to expanded polypropylene at the same foaming magnification, contributes to a car's crucial collision safety performance and vibration absorption.

The accuracy of clearance between parts is important in a car that is a collection of tens of thousands of parts.

Since PIOCELAN has excellent dimensional stability during molding and can accommodate complex designs, we provide parts that fit perfectly into place.

Fitting perfectly and absorbing shocks play a role in the reduction of chattering and creaking noises during driving.

Chemical and oil resistance between peripheral parts is an important factor in maintaining the performance of ultra-durable products for a car that is made by combining various materials such as steel, aluminum, glass, plastic, carbon fiber, leather, fabric, and rubber.

The high chemical and oil resistance of PIOCELAN allows it to maintain its performance for a long time without being affected by peripheral parts.

The enhancement of safety performance, driving performance, and comfort and the reduction of fuel consumption are conflicting requirements from the perspective of vehicle weight. Therefore, modern car development has focused on reducing the weight by one gram.

PIOCELAN uses less material than polypropylene when making a molded product with the same rigidity as a molded product using conventional polypropylene. In other words, PIOCELAN can produce parts with the required performance using less material, which contributes to weight reduction.

PIOCELAN is produced using Sekisui Kasei's proprietary polymer hybrid technology, and its main feature is that it can be molded and processed using general-purpose equipment.

In addition to the weight reduction effect mentioned above, we have established a highly efficient supply system by delivering products from the base closest to the customer from among Sekisui Kasei's production bases around the world, thereby keeping material costs, logistics costs, and time costs low.

A video panel that shows the rapidly evolving high-tech products. It was a cube screen in the cathode-ray tube era, but in modern times, it is no exaggeration to say that it is a "fragile, thin and large board".

Both finished products and the product parts of home electric appliances and IT products are all precise and delicate. PIOCELAN is widely used in various applications such as a shock-absorbing packing material for flat-panel TVs, which are becoming increasingly larger around the world, and distribution boxes for liquid crystal panels. It is also widely used as a packing material by major consumer electronics and IT product manufacturers.

Compared to conventional packing materials, thinning and high foaming becomes possible with PIOCELAN, which greatly contributes to cost reduction and improved transportation efficiency by slimming down the packing size. It can also contribute to environmental conservation by saving resources and reducing weight. The following is an introduction of the properties of PIOCELAN that are being utilized.

The Sekisui Kasei Group has certified "packing materials for transporting automobile parts" and "containers for transporting flat-screen TV glass and panels", which are molded products using PIOCELAN, as "sustainable star products" (environmentally friendly products) *.

Certification criteria established as part of the action plan "SKG-5R" to realize the "contribution to a sustainable society" set forth by the Sekisui Kasei Group (SKG). We internally certify products that reduce environmental impact and take into consideration limited resources as "Sustainable Products", and products that have a particularly high degree of contribution to the environment as "sustainable star products" (environmentally friendly products), thereby promoting their creation and market expansion.

Flat-panel TVs and video panel members are now being distributed all over the world. However, many possibilities of damage arise during transportation of these products, such as rolling and pitching of transport ships due to bad weather conditions at sea and severe vibration due to local road conditions.

PIOCELAN, which exhibits 1.2 times higher impact resistance when compared to expanded polypropylene at the same foaming magnification, ensures protection and damage prevention of the inside of products and parts from impact during transportation.

Being able to transport a large number of products at one time is an important issue in logistics.

The combination of PIOCELAN's high rigidity and dimensional stability makes it possible to achieve a design that maintains rigidity while being thinner than conventional packing materials, which makes it possible to reduce the size of the transport box. As a result, the number of products that can be transported at one time increases, contributing to reduced transportation costs and more efficient logistics.

As the panel size increases, in the case of polypropylene, panel-to-panel contact occurs due to panel deflection caused by insufficient rigidity, but the highly rigid PIOCELAN offers delivery boxes and other products designed to avoid this problem.

Cushioning materials and packing materials have to become denser, thicker, and heavier when transporting fragile products safely. As a result, they lead to an increase in transportation costs.

PIOCELAN uses less material than polypropylene when making products with the same performance as conventional polypropylene. This means that the required performance can be achieved with less material, which contributes to weight reduction.

PIOCELAN is produced using Sekisui Kasei's proprietary polymer hybrid technology, and it has the advantage of being able to be molded and processed using general-purpose equipment.

In addition to the aforementioned weight reduction effect, we have built a highly efficient supply system by delivering products from the production base closest to the customer from among Sekisui Kasei's worldwide production bases, thereby keeping material costs, logistics costs, and time costs low.

Please feel free to contact us

should you have any comments or questions.